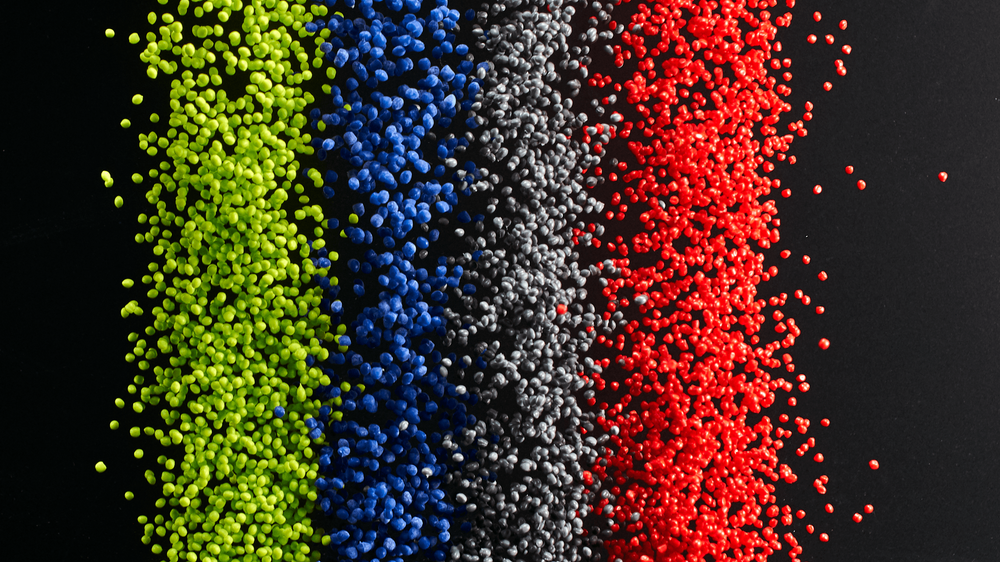

ALLRUNA® Compounds

Proven in numerous industries

Our ALLRUNA® compounds have proven themselves in numerous industries – from automotive to medical technology. Here you will find examples and requirements from various application areas.

Versatile

ALLRUNA® compounds are suitable for a wide variety of applications.

Customized

Each formulation is developed specifically for your requirements.

Application examples & markets

Discover TPE applications in practice. Click on the markers to learn more about specific ALLRUNA® components.